Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

How to Choose the Right Forklift Attachment for your Food and Drink Business

By Jason Cadman on May 19, 2025

In our previous blog, we looked at the benefits of using specialised forklift attachments in food and drink manufacturing. We touched upon how investing in the right tools can reduce costs, limit damage, and streamline business processes, and how ‘making do’ isn’t the safest, most productive, or efficient way of working.

But once you’ve decided to invest in specialised forklift attachments to help you to gain (and maintain) that competitive edge, how do you know which attachments are right for your business? In this blog, we take a closer look …

In the food and drink sector, there are a number of ever-evolving rules and regulations that must be complied with to uphold health and safety. So when choosing equipment, relevant legislation, the environment in which you intend to use it, and the desired outcome must all be considered to ensure your attachment of choice is (and remains) fit-for-purpose, compliant, and - most importantly - safe.

Various pieces of legislation and regulatory standards can influence the decision on the right forklift truck attachment - from the Food Safety Act 1990 and the Food Hygiene (England) Regulations 2013 to the Health and Safety at Work Act 1974 and LOLER 1998. Hygiene, safety, and operational requirements all come into play.

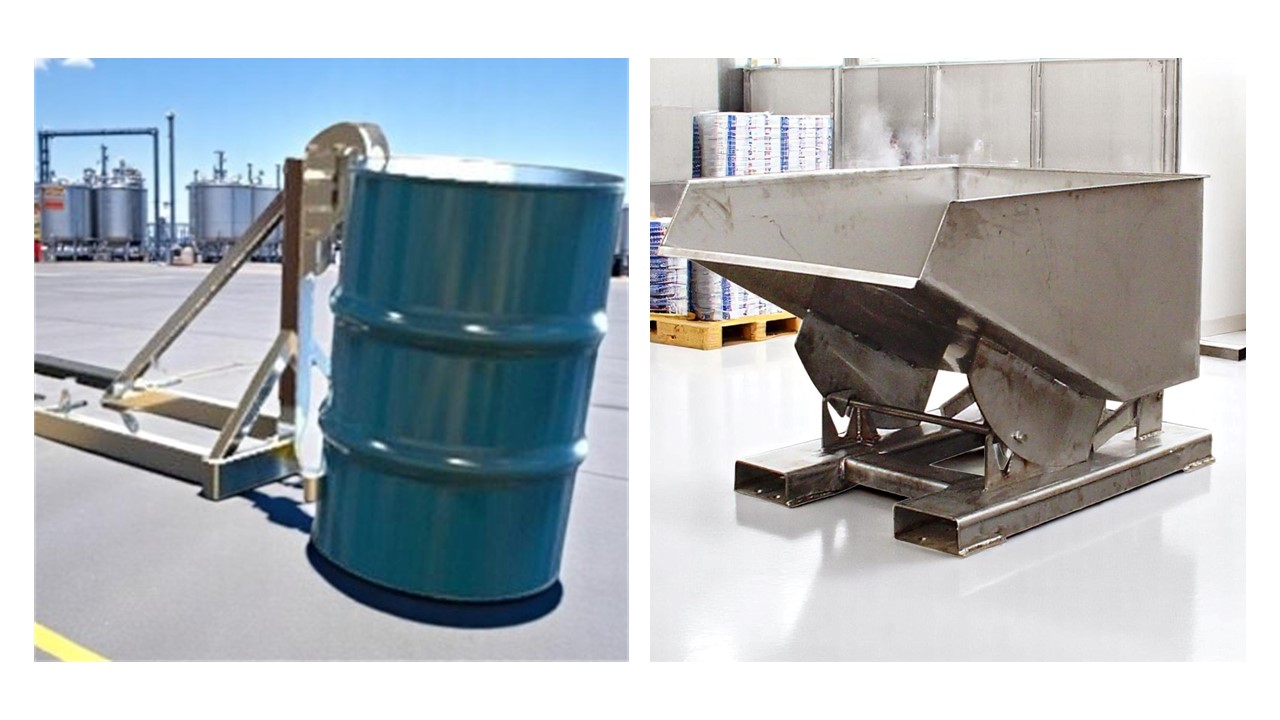

To remain compliant it’s important to choose attachments that will not compromise food hygiene - manufactured from materials that are non-absorbent, non-toxic, and that won’t flake or rust and contaminate food. They must also be designed to allow for effective cleaning and disinfection, and so the attachment cannot trap dirt. And if the attachments are to be used in chilled areas, they must meet even stricter hygiene requirements.

Stainless steel is an excellent choice for food-safe attachments for the food and drink sector due to its non-corrosive properties and its ability to be pressure washed to maintain cleanliness and hygiene standards.

Environment

Various factors come into play here such as whether the attachment is to be used in hygiene or allergen sensitive areas, cleanrooms, moisture rich or wet environments, or temperature controlled conditions like cold stores or freezers.

For example, cold temperatures can cause standard hydraulic systems to fail and some materials can become cracked or brittle when frozen, so it’s important to choose low-temperature rated seals, hydraulics and lubricants to stay compliant with legislation pertaining to temperature tolerance.

Again stainless steel is a good choice in these environments due to its corrosion-free make-up, as are galvanised components. Similarly hot environments can cause damage to unprotected materials and so heat-resistant seals and rust-resistant materials should be sought.

Moisture and humidity issues can plague the food and drink sector particularly, such as in drink bottling environments or in those all-important washdown zones, so sealed components and non-corrosive materials are a must, as is protecting any hydraulic or electrical parts with IP-rated enclosures.

Desired outcome

Last but by no means least, the desired outcome determines the functionality, performance and safety needed during material handling. Whether it’s maximising product protection to prevent costly damage, improving efficiency and reducing manual handling, reducing waste, or ensuring safety and stability - choosing the right attachment must be a carefully measured decision to ensure it is always fit for its intended purpose.

At Contact, we’re always on hand to help you make the right forklift attachment choice for your unique material handling needs, so do reach out to us today for a friendly no obligation chat.

Latest News